Compressed air is an important power source in industrial manufacturing and many other fields. However, with the rise in energy costs and the improvement of environmental standards, how to use and manage compressed air systems more efficiently has become a focus of attention. The combination of air compressor and temperature control valve can optimize the efficiency of compressed air usage, while reducing energy consumption and equipment wear.

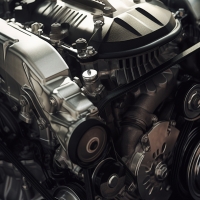

1、 Working principle and challenges of air compressor

An air compressor is a device used for compressing air, which converts atmospheric pressure into air with a certain pressure through mechanical means. Air compressors play a crucial role in many applications, such as gas supply, driving tools, material conveying, etc. However, air compressors will face some challenges during operation. For example, overheating may lead to a decrease in equipment efficiency, and in severe cases, it may even damage the equipment. In addition, unstable pressure supply may affect the continuity of the production process and product quality.

2、 The function of temperature control valve

A temperature control valve is a type of valve used to automatically regulate the temperature of a fluid. In the air compressor system, the temperature control valve can sense the operating temperature of the air compressor and adjust the air flow entering the air compressor as needed. In this way, the temperature control valve can help maintain the normal operating temperature of the air compressor, preventing overheating and excessive cooling.

3、 Collaborative operation of air compressor and temperature control valve

By combining the air compressor with a temperature control valve, precise control of the operating status of the air compressor can be achieved. The temperature control valve can adjust the air flow entering the air compressor according to its actual operating temperature, thereby maintaining a stable operating temperature of the air compressor. This collaborative working method can not only improve the operating efficiency of the air compressor, but also extend the service life of the equipment.

4、 Efficiency improvement and energy conservation and consumption reduction

By precisely controlling the operating temperature of the air compressor, its operational efficiency can be significantly improved. Overheating may lead to a decrease in equipment efficiency, while excessive cooling may result in unnecessary energy consumption. By automatically adjusting the temperature control valve, it is possible to ensure that the air compressor operates within the optimal temperature range, thereby improving its operational efficiency. In addition, by maintaining a stable pressure supply, product quality issues and production interruption risks caused by pressure fluctuations can be reduced.

5、 Equipment maintenance and safety management

The temperature control valve can also help monitor the operating status of the air compressor. If the air compressor malfunctions or has abnormal conditions, the temperature control valve may sound an alarm or close the valve to prevent further damage. This security mechanism helps reduce equipment failures and maintenance costs, while improving overall production efficiency.

6、 Conclusion

The above is the analysis of the application of temperature control valves in air compressors by Yingkai Valve Industry. The combination of air compressors and temperature control valves can achieve more efficient and stable compressed air supply. By precisely controlling the operating temperature and pressure of the air compressor, the operating efficiency of the equipment can be improved, energy consumption and equipment wear can be reduced, and the safety and stability of the production process can be enhanced. This collaborative work approach is of great significance for improving the overall operational efficiency of industrial manufacturing and other fields.

ENKAIR temperature control valve is not only fully compatible with AMOT temperature control valve, HB Herberger temperature control valve, German BEHR temperature control valve, Vmc temperature control valve, etc. in terms of installation size, but also has superior performance.

At present, ENKAIR temperature control valve has been successfully equipped with international first tier brand compressors, such as GD Gardner Denver, Sullair, Ingersoll Rand Group, Atlas Copco, Quincy, Fusheng, as well as GE Transportation, Kai ShanGroup, Yangma Yanmar engine, York Air Conditioning Chiller, etc. For specific parameters, please contact Yingkai Valve for confirmation.