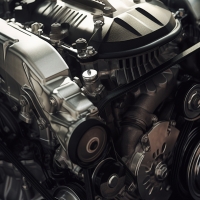

In many fields of industrial production, hydraulic lubrication equipment is like the "power heart" of mechanical systems, providing critical support for its stable operation. In this complex and critical system, temperature control valves are playing an indispensable role.

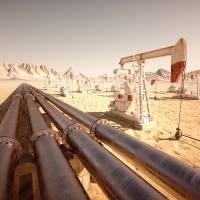

The core mission of the temperature control valve, a sophisticated device, is to precisely regulate the oil temperature in hydraulic lubrication equipment. The stability of oil temperature directly affects the performance and reliability of the entire equipment. When the oil temperature is too high, the viscosity of the oil drops sharply, the lubrication effect is greatly reduced, the degree of equipment wear increases, and the risk of failure also increases significantly; On the contrary, when the oil temperature is too low, the fluidity of the oil becomes sluggish, the response speed of the system slows down, and the work efficiency will also be seriously affected. Our products are widely used in various fields such as diesel engines, compressors, hydraulic lubrication equipment, new energy vehicles, wind power equipment, boilers, air conditioning and refrigeration equipment, ships and oceans, oil and gas, etc. Compact structure, wide applicable flow range, flexible installation position, easy operation, superior seismic and impact resistance, built-in sensing design, adaptive adjustment, and excellent quality. Yingkai self operated temperature control valve is fully compatible with AMOT, HB Holbiger, Germany BEHR, Vmc, Sullair, Kaishan, AKO, FPE, Vmc, Quincy, Atlas, Fusheng, GD Dengfu, and various air compressors, compressors, diesel engines, boilers, water stations, lubricating oil stations, water chillers, German GEA compressors, German WAT refrigeration unit temperature control valves, etc. in terms of installation dimensions. Please contact Yingkai Valve Industry for specific parameters confirmation.

In order to maintain the ideal state of oil temperature, temperature control valves have emerged. It is like an agile "guardian" that can flexibly adjust the flow rate of cooling or heating media based on subtle changes in oil temperature. When the oil temperature exceeds the preset upper limit, the temperature control valve quickly opens the cooling channel, allowing the cooling medium to rush through and quickly take away excess heat, causing the oil temperature to fall back obediently; When the oil temperature approaches the set lower limit, the temperature control valve decisively closes the cooling channel and opens the heating channel to inject warmth into the oil, ensuring that the oil temperature quickly returns to the normal range.

Let's take a look at specific application cases. In the hydraulic system of a hydraulic electromechanical company in Chongqing, a self operated three-way temperature control valve has demonstrated its capabilities. It has specific parameter configurations, such as a center to center distance of 85mm for screw holes and four 14mm diameter screw holes. Its material is 304 stainless steel, which can adapt to environments with l-dab100 lubricating oil as the medium. The temperature can be freely adjusted between 28-70 ℃, and the flow rate can reach 32l/min. This temperature control valve does not require an external power supply, making it cost-effective and easy to install and maintain. Based on the principle of liquid thermal expansion and contraction, the valve opening is precisely controlled by the change in liquid volume inside the temperature sensing bag, effectively controlling the flow rate of the heat source medium and ensuring stable oil temperature.

A general machinery manufacturing enterprise has introduced self operated temperature control valves in its heat exchange equipment for production conditions. It can handle heat exchange conditions of steam, hot water, hot oil and other media with ease and automatically adjust the temperature. During the operation of the equipment, as the oil temperature fluctuates, the temperature sensing element of the temperature control valve responds sensitively and adjusts the medium flow rate in real time, effectively avoiding abnormal fluctuations in oil temperature.

A certain air conditioning refrigeration equipment manufacturer has installed self operated three-way temperature regulating valves in the heat exchangers and heat exchange units of the air conditioning refrigeration system. By carefully setting the temperature range, this temperature control valve can automatically and accurately adjust the flow rate of the refrigerant medium according to changes in indoor temperature, keeping the indoor temperature constant at all times.

In the field of marine equipment manufacturing, a certain manufacturer has equipped temperature control valves for the hydraulic and lubrication systems of ships. Considering the variability of ship navigation environment, the temperature of hydraulic oil and lubricating oil is easily affected. The existence of temperature control valves ensures that the temperature of these media is always within the appropriate range, providing protection for the stable operation of the system.

In the chemical production process of a certain chemical enterprise, some equipment's lubricating oil system adopts self operated three-way temperature regulating valves. Faced with complex chemical reactions and process, temperature control valves effectively control oil temperature, ensuring normal lubrication and efficient operation of equipment, significantly reducing equipment wear and failure.

In summary, there are countless application cases of temperature control valves in hydraulic lubrication equipment. They play a crucial role in their respective fields, improving equipment efficiency, stability, and reliability through precise temperature control, extending equipment lifespan, and reducing maintenance costs. In the future industrial development, we believe that temperature control valves will continue to innovate and evolve, contributing to the optimization and operation of various equipment.