Is your compressor failing to cool or your diesel engine overheating? The "hidden culprit" might be it!

2025-08-06 英凯阀业

In the sweltering summer, the diesel engine on the construction site roars continuously, yet the cab remains unbearably stuffy; the cold storage compressor runs at full capacity, but its refrigeration effect is greatly reduced... Behind these annoying problems, there may be a low-key yet crucial "body temperature regulator" - the temperature control valve (thermostat).

In the industrial field, whether it is the diesel engine that drives huge ships or the compressor that ensures cold chain logistics, one of the core secrets to stable operation is precise temperature control. And the temperature control valve is the key sentinel guarding this line of defense!

I. Guardian in the Heat Wave: Why Do Industrial Equipment Need a "Body Temperature Steward" More?

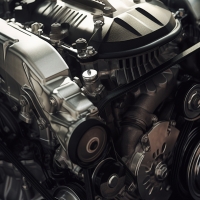

The "fiery" challenges of diesel engines:

- Ultra-high compression ratio: The compression ratio of diesel engines is much higher than that of gasoline engines (up to 18:1 or more), resulting in extremely high pressure and temperature in the combustion chamber.

- Heavy load operation: Construction machinery, ships, and generators often need to work at full load for a long time, resulting in huge heat loads.

- Turbocharging: Supercharged diesel engines have higher intake temperatures, further increasing the heat load.

Consequences of loss of control: Overheating leads to oil failure, piston scuffing, cylinder head deformation, or even cylinder explosion; excessive cold causes poor combustion, severe carbon deposition, increased wear, and excessive emissions.

The "hot and cold" game of compressors:

- Refrigeration compressors: While efficiently compressing refrigerants to generate low temperatures, they produce a lot of waste heat due to friction and the compression process itself. Excessively high oil temperature leads to lubrication failure and reduced refrigeration efficiency; excessively low temperature causes difficulty in oil return and wear.

- Air compressors: Compressing air generates high temperatures. If the exhaust temperature is out of control, it will at least accelerate the aging and carbon deposition of lubricating oil, or even trigger explosion risks (especially oil-injected screw compressors)!

- Process gas compressors: Have strict requirements on the gas outlet temperature, which directly affects subsequent processes.

Conclusion: Industrial equipment operates in harsher environments, with heavier loads, and is more sensitive to temperature! Precise temperature control is the lifeline for efficient, reliable, safe, and long-life operation. The temperature control valve is the intelligent "temperature switch" of this system.

II. Core Secret of Temperature Control Valves: The "Thermal Expansion Power" of Paraffin

Whether it is a diesel engine or a compressor, the core principle of mainstream temperature control valves is surprisingly consistent: using the physical expansion of temperature-sensitive materials to drive the valve! (The most common is high-purity paraffin)

1. "Heart" - Temperature-sensing element:

A sealed small copper can filled with specially formulated paraffin.

Paraffin is extremely sensitive to temperature, and its volume expands significantly and stably when heated.

2. "Muscle" - Push rod mechanism:

The huge pressure generated by the expansion of paraffin pushes the internal rubber diaphragm.

The diaphragm pushes the sturdy metal push rod to extend outward.

3. "Arm" - Valve action:

The linear movement of the push rod is converted into the rotation or lifting movement of the valve through an exquisite mechanical structure (such as a lever or slider).

At low temperatures: Paraffin shrinks, the valve closes (or opens the bypass), restricting the flow of coolant/lubricating oil to the main radiator/cooler, promoting rapid heating of the equipment (or maintaining the necessary temperature).

When the set temperature is reached: Paraffin expands, pushing the valve to gradually open the main path (and possibly close the bypass), allowing coolant/lubricating oil to flow to the radiator/cooler for efficient heat dissipation.

The set temperature is crucial! Different equipment and different design requirements have different opening temperature points for the temperature control valve (e.g., common diesel engine temperatures are 82°C, 88°C, 95°C; compressors vary more depending on the type). This "switch point" is precisely determined by the paraffin formula and mechanical structure.

III. Diesel Engine Temperature Control Valve: Maintaining the Stability of "Surge Power"

Core function: Precisely manage the circulation path of coolant in the engine block and cylinder head water jackets.

Working modes:

- Cold start/low temperature: The temperature control valve closes the main water circuit, and the coolant only circulates in a small loop inside the engine and the heater core (if any), quickly warming up the engine, reducing cold wear, and improving combustion and emissions.

- Normal temperature: The temperature control valve opens, and the coolant flows to the radiator for large circulation heat dissipation, maintaining the optimal operating temperature (about 85-95°C), ensuring power, economy, emissions, and service life.

Serious consequences of failure:

- Normally closed: The engine rapidly overheats and "boils", leading to cylinder scuffing, cylinder head gasket damage, or even deformation and scrapping of the engine block!

- Normally open: Slow warm-up, no heater in the cab in winter, high fuel consumption, poor power, severe carbon deposition, and increased long-term wear.

IV. Compressor Temperature Control Valve: Ensuring the Balance of "Hot and Cold Conversion"

Temperature control valves on compressors mainly manage the cooling path of lubricating oil or compressed gas (with various specific forms):

1. Oil circuit temperature control (critical!):

- Cold start/low load: The valve (or bypass valve) prevents or reduces oil flow to the oil cooler, allowing the oil temperature to quickly rise to the optimal viscosity range (usually 40-70°C) to ensure good lubrication and oil return.

- High temperature/high load: The valve opens, guiding hot oil to the oil cooler for heat dissipation, preventing excessive oil temperature (usually not exceeding 90-100°C), and avoiding oxidation coking, lubrication failure, and aging of seals.

Application: Widely used in screw air compressors, refrigeration compressors, etc.

2. Gas circuit temperature control (specific needs):

In some process gas compressors or air compressors with strict restrictions on exhaust temperature, the temperature control valve may directly adjust the flow of cooling water into the gas cooler to precisely control the exhaust temperature, meeting process or safety requirements (such as preventing the exhaust temperature of air compressors from exceeding safety limits).

3. Impact of failure:

- Oil temperature out of control: Excessively high temperature causes oil deterioration, carbon deposition, bearing wear, and main engine seizure; excessively low temperature leads to high viscosity, difficulty in starting, poor oil return, and risk of emulsification.

- Exhaust temperature out of control: Excessively high temperature may cause safety accidents (for air compressors) or disrupt subsequent processes; excessively low temperature may lead to condensation and damage equipment.

V. How to Make This "High-Temperature Guardian" Stand Faithfully?

Industrial equipment is of high value, and the loss from downtime is huge, so the maintenance of temperature control valves is crucial:

1. Choose "blood" carefully: Be sure to use the coolant (for diesel engines) or lubricating oil/grease (for compressors) of the type and grade specified by the equipment manufacturer. Poor-quality oil and fluid are the main causes of jamming and corrosion of temperature control valves!

2. "Change blood" regularly: Strictly follow the maintenance manual to replace coolant and lubricating oil. Aging and deteriorated oil and fluid will lose their protective properties and produce sludge that clogs the temperature control valve.

3. Keep "clean": Ensure that the cooling system (radiator, intercooler, oil cooler) is clean and unobstructed. Scale and blockages directly affect heat dissipation efficiency, forcing the temperature control valve to work at its limit.

4. Observe keenly: Pay close attention to the water temperature gauge (for diesel engines), oil temperature gauge/exhaust temperature gauge (for compressors) on the equipment dashboard. Any abnormal temperature fluctuations are dangerous signals!

5. Professional "physical examination" and "treatment": Conduct regular professional maintenance and inspections. Once a temperature control valve failure is suspected (such as slow heating, overheating, or abnormal oil temperature), it must be diagnosed and replaced by professionals. Choose original or equivalent high-quality temperature control valves to ensure their temperature-sensing accuracy and reliability.

Whether it is a roaring diesel engine or a silent compressor, the temperature control valve is on the core thermal management battlefield, silently performing its duty of precise regulation. Though small, it is the "unsung hero" that ensures the efficient, stable, and safe operation of industrial giants.