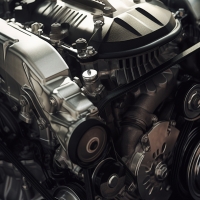

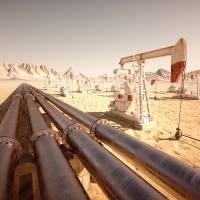

Large air compressor units are indispensable and important equipment in many industrial fields. Widely used in industries such as biological fermentation and petrochemicals. These industries have one thing in common, which is that they are usually produced continuously. Therefore, the safe and stable operation of the air compressor unit is very important. It is difficult to restore the operation of a large air compressor unit in a short period of time once an abnormal shutdown occurs. If there is a shortage of backup units, it will inevitably cause incalculable losses to the company's production. They are typically used to compress air to drive machines and equipment. However, these machines may also pose safety risks, especially in terms of the safe operation of air compressor units. Temperature control valve is one of the key components to ensure the safe operation of large air compressor units. This article discusses the safe and stable operation of large air compressors with peers based on the actual production line.

A temperature control valve is a type of valve that controls temperature by sensing the temperature of the medium and adjusting the valve opening to maintain a predetermined temperature. In large air compressor units, temperature control valves can be used to control the air temperature to ensure that it operates within a safe range. If the air temperature is too high, the temperature control valve will automatically close the air compressor unit to avoid overheating and damage.

The importance of temperature control valves lies in their ability to ensure the safe operation of large air compressor units. When the temperature of the air compressor unit is too high, the temperature control valve will automatically close to prevent overheating and damage. This helps prevent the occurrence of fires, explosions, and other safety issues. In addition, the temperature control valve can also help users monitor the temperature of the air compressor unit, so as to take timely measures to prevent overheating.

In order to ensure the safe operation of large air compressor units, temperature control valves need to be regularly maintained and replaced. This is because over time, the valve may fail or experience other issues that can affect its performance. In addition, users also need to regularly check the sealing of the valve to ensure its normal operation.

In short, the temperature control valve is one of the key components for the safe operation of large air compressor units. It can help users monitor and control air temperature, and ensure that the air compressor unit operates within a safe range.

Changzhou Yingkai Valve Industry Co., Ltd. - an innovative enterprise specializing in the production of temperature control valves. We are committed to providing high-quality temperature control valve cores, temperature control valves, temperature sensing elements, and thermal sensing elements, and have obtained ISO9001 quality management system certification. Our products are widely used in various fields such as diesel engines, compressors, hydraulic lubrication equipment, new energy vehicles, wind power equipment, boilers, air conditioning and refrigeration equipment, ships and oceans, oil and gas, etc. The product highlights include compact structure, wide applicable flow range, flexible installation position, easy operation, superior seismic and impact resistance, built-in sensing design, adaptive adjustment, and excellent quality. Welcome new and old customers to call for consultation and discuss cooperation!